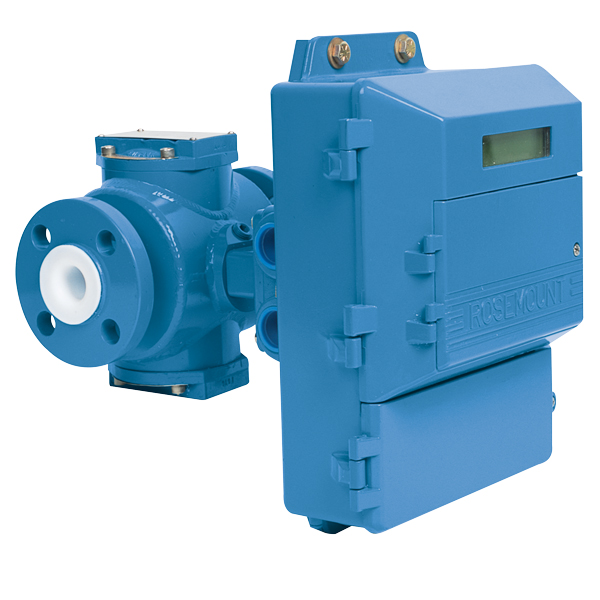

The digitalYEWFLO Reduced Bore Type Vortex Flowmeter features a cast stainless steel body and a concentric reducer and expander that enable stable flowrate measurements in low-flow conditions. This model reduces installation cost and expands the range of applications available to customers.

Downloads for digitalYEWFLO (DY-RB)

Features: digitalYEWFLO Reduced Bore Type Vortex Flowmeter

| |

| - | No longer is it necessary to change the orifice plate to adjust for changes in the flow rate. |

| - | Totalization and self-diagnostic functions are available for enhanced flowrate management. |

| ||

| <Conventional configuration> | ||

| - | Installation is difficult, involving many different nuts, bolts, and gaskets. | |

| - | Customer must provide reducers and extension tubes. | |

| - | There are six connection points, each of which is a potential leak point. | |

| ||

| ||

| <The reduced bore digitalYEWFLO solution> | ||

| - | Expanded low flow measurement range | |

| - | Easy to install | |

| - | Requires no additional parts | |

| - | There are only two connection points -- meaning there are fewer locations where leaks can occur. | |

| - | The same face-to-face dimensions eases the task of installing other sizes or types of digitalYEWFLO flowmeters. | |

| ||

| While formerly two different types of orifice plates had to be changed to adapt to fluctuations in the line flow rate, this is no longer necessary with the digitalYEWFLO reduced bore type. In lines that require annual or long-term flow maintenance, the digitalYEWFLO eliminates the need to interrupt the flow to perform this work. Yokogawa vortex flowmeters are well suited to high temperature and high pressure applications, and the quality of flow management can be improved even further through the use of anti-vibrating efficiency and self diagnostic functions that rely on the digitalYEWFLO's SSP system. |

Specifications: digitalYEWFLO Reduced Bore Type Vortex Flowmeter

| Standard | Multi-Variable | Reduced Bore | |

| Model & code | DY Vortex Flowmeter | Optional code:/MV | Option code:/R1,/R2 |

| Fluid to be measured | Liquid, gas, steam (avoid multiphase flow and sticky fluids) | ||

| Nominal size | 15mm ∼ 300mm (400mm:special) | 25mm ∼ 200mm | 25mm ∼ 200mm |

| Accuracy | Liquid: ±1.0% of reading (20000≤Re≤1000) Liquid: ±0.75% of reading (D×1000≤Re) | Liquid: ±1.0% of reading (20000≤Re≤1000) | |

| Gas, steam: ±1.0% of reading (flow velocity less than 35m/s) Gas, steam: ±1.5% of reading (flow velocity 35m/s ∼ 80m/s) | |||

| Output signal | Simultaneous output(both analog and transistor contact output available) | ||

| Process temperature range | -29 deg C - 260 deg C (standard) | -29 deg C - 260 deg C (standard) | -29 deg C - 260 deg C (standard) |

| -196 deg C∼100 deg C (option: cryogenic version) | N/A | N/A | |

| -29 deg C∼450 deg C (option: high process temperature version) | N/A | -29 deg C∼450 deg C (option: high process temperature version) | |

| Process pressure limit | -0.1MPa (-1kg/cm2) to flange rating | ||

| Ambient temperature | -29 to 85 deg C (Integral type / No indicator) -29 to 80 deg C (Integral type / with indicator) -29 to 85 deg C (Remote type detector) -40 to 85 deg C (Remote type converter / No indicator) -30 to 80 deg C (Remote type converter / with indicator) | ||

| Ambient humidity | 5~100%RH( Non-condensing) | ||

| Mounting | Integral type and Remote type detector: Flange mounting or wafer mounting Remote type converter: 2 inch pipe mounting JIS10/20/40, ANSI150/300/600/900, JPI150/300/600,DIN PN10/16/25/40 | ||

| Electrical connection | JIS G1/2 female, ANSI 1/2NPT female, ISO M20×1.5 female | ||

| Electrical classification | JIS flameproof, FM explosion proof/intrinsically safe ATEX (CENELEC flameproof/intrinsically safe/IEC type n) CSA explosion proof/intrinsically safe : Dual Seal SAA flame proof/intrinsically safe | ||

| Material | Body: SCS14A cast stainless steel (equivalent to SUS316,CF8M) Shedder bar: duplex stainless steel (option:anti-corrosion version) Gasket: SUS316 stainless steel with polytetrafluoroethylene (Teflon) coating Converter housing and case cover: aluminum alloy or ASTM CF8M (equiv. JIS SCS14A) (Option: /E1) | ||

| Applicable Standard | *EMC Conformity Standards: EN61326-1 Class A, Table 2 (For use in industrial locations), EN61326-2-3 EN55011 Class A Group 1 *Pressure Equipment Directive: Notified Body Identification Number 0038 Module H | ||

To start your quick quote, please fill out the below form and an China Industry Automation representative will contact you within an hour.

Receive a reply within 30 minutes, when you submit a Quick Quote Request Monday-Friday between 8:30 a.m. and 6:00 p.m. CST. Requests received outside of these hours will receive a reply the next business day.